Acrylic sheets (also often called plexiglass) come in a variety of sizes and colors, with clear acrylic being particularly eye-catching. Clear acrylic is clearer than glass and has approximately 10 times the impact resistance of traditional glass. Combining superior strength and aesthetics, it is an ideal material for professional craftspeople and DIY enthusiasts, and is widely used in a variety of projects: from decorative art pieces and display cases to protective covers and functional panels. For example, acrylic sheets are often used to make pool shells or to create spa tubs

In this article, we will explain how acrylic sheets are cut industrially.we'll use our finished products to demonstrate to interested friends how to cut acrylic sheets.

(Friendly reminder: If you choose to cut it yourself at home, please prepare appropriate equipment and take safety precautions to prevent injury)

Cast acrylic is more brittle, prone to chipping during cutting, and requires slower rotation/feed speeds; extruded acrylic is more flexible and easier to cut.

Thin sheets (≤3mm): Can be cold-cut manually (utility knife/panel cutter);

Medium-thick sheets (3-10mm): Power tools recommended (jigsaw/circular saw/laser cutter);

Thick sheets (>10mm): CNC engraving machine/CNC is preferred, or multiple cuts in stages.

Clean the sheet surface and apply masking tape (to prevent scratches and reduce chipping);

Secure the sheet with clamps (to prevent displacement during cutting);

Mark the cutting lines (using a pencil and ruler, ensuring clear lines and allowing 1-2mm for sanding).

Tools: Utility knife (hook knife/special acrylic cutting knife recommended)

straightedge

backing plate (wooden board/MDF)

sandpaper (200-grit + 400-grit).

Steps:

1. Apply masking tape to the acrylic sheet, and repeatedly score the cutting line along the straightedge with the utility knife (apply even pressure, cut through the surface layer each time, at least 10-20 scores)

2. Align the scored line with the edge of the backing plate, hold both sides of the sheet firmly with both hands, and bend it downward quickly (thin sheets can be broken off in one go)

3. Sand the cut surface with sandpaper (from coarse to fine) to remove burrs and chipping.Notes: Only suitable for straight-line cutting; bend quickly to avoid delamination of the sheet

Tools: Jigsaw, special acrylic saw blade (fine teeth, ≥18TPI to avoid chipping from coarse teeth), vacuum cleaner (to absorb debris).

Steps:

1. Secure the sheet, align the saw blade with the cutting line, and start the jigsaw (low speed gear, rotational speed ≤3000rpm)

2. Keep the saw blade perpendicular to the sheet during cutting, feed at a slow speed (1-2cm per second), and do not force forward

3. For curved cuts, turn slowly at small radii to avoid jamming the saw blade

4. Treat the cut surface with sandpaper + polishing paste after cutting

Notes: Ensure the saw blade is sharp; continuously blow air/vacuum during cutting (acrylic debris sticks to the saw blade at high temperatures, causing chipping).

Tools: Circular saw, special alloy saw blade for acrylic (fine teeth, 60-80 teeth, no gullet), workbench, clamps.

Steps:

1. Secure the sheet on the workbench, align the cutting line with the edge of the workbench, and reserve space for the saw blade to run;

2. Set the circular saw to low speed (rotational speed 4000-5000rpm), and adjust the saw blade depth to 2-3mm deeper than the sheet thickness;

3. Feed forward at a constant speed (about 5cm per second) along the cutting line, and blow away debris with a low-pressure air gun at the same time;

4. After cutting, rough-grind with a file, then finish-grind with sandpaper.

Notes: Do not cut at high speed (high temperatures will melt the acrylic edge); the saw blade must be perpendicular to the sheet to avoid chipping from bevel cutting.

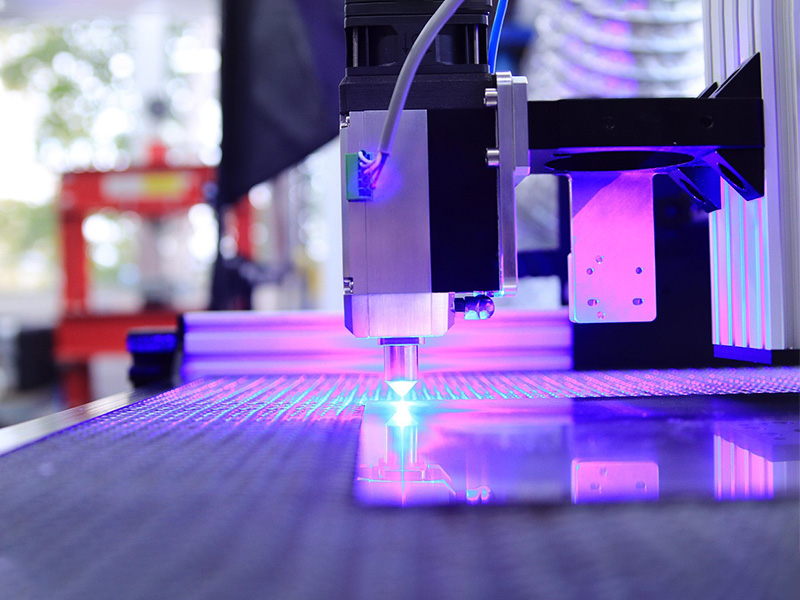

Tools: CO2 laser cutting machine

Steps (general parameter reference):

1. Import the cutting drawing (CAD/AI format), set parameters: speed 5-15mm/s, power 60%-80%, single-pass cutting (multi-pass cutting for thick sheets)

2. Secure the sheet on the laser machine workbench, focus, and start cutting

3. Wipe the cut surface with alcohol after cutting (laser-cut surfaces are smooth and only require slight polishing).

Advantages: No chipping, high precision (±0.1mm), can cut complex patterns/hollowouts

Disadvantages: High equipment cost, suitable for mass production.

Tools: CNC router, single-flute spiral milling cutter (special for acrylic).

Core parameters: Rotational speed 18000-24000rpm, feed rate 800-1500mm/min, cutting depth 1-2mm per pass (multi-pass cutting for thick sheets).

Advantages: High automation, can batch process complex shapes, extremely high precision of cut surfaces

Disadvantages: High equipment cost, suitable for enterprise-level use.

web:https://pixabay.com/ author:OptLasers

Post-Cutting Treatment

1. Sanding: First rough-grind with 180-240 grit sandpaper (remove burrs/chipping), then fine-grind with 400-800 grit, and finally polish with 1000+ grit;

2. Flame Polishing (optional): Gently sweep the cut surface with a special flame polisher (or alcohol lamp), the acrylic will polish quickly when exposed to high temperatures (control the flame to avoid scorching);

3. Cleaning: Wipe the sheet surface with alcohol + lint-free cloth to remove masking tape residue and debris.

If you need acrylic sheets of the appropriate size, please feel free to order from LiangJing. Order now or contact us with any questions.